The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and

2017年10月25日 In practical terms, one must assume some mill diameter, usually about 150 mm (6 inches) less than the mill inside shell or

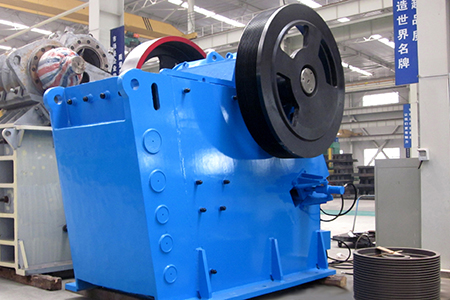

The circuit comprises a SAG mill, 12 m diameter by 6.1 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with

Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break

2022年11月1日 Unlike in laboratory ball mills, various designs in liner shape, including lifting and classifying liners, have been developed to increase milling performance in full

Ball mill liners are an essential component in the operation of a ball mill, offering protection, improved efficiency, and reduced noise levels. Whether you are in the mining or mineral processing industry, understanding the

Ball mills, conversely, contain grinding media up to 50mm in diameter, occupying between 25% - 40% of mill chamber volume. To effectively reduce material size, each type of mill

Bradken is a leading engineered grinding mill solutions provider, supported by in-house design and manufacture of high-quality mill liner components to suit AG/SAG, Ball and Rod Mills. By utilising the latest research and

حقوق الطبع والنشر: شركة خنان ليمينغ لتكنولوجيا الصناعة الثقيلة المحدودة. رخصة أعمال